Ways to differentiate purifier

Purifier can be classified in many ways and in fact to differentiate it itself is an interesting subtopic of discussion as there are too many ways base on how we see it through the experiences, readings, personal opinions as long as it not out of topic.

Into the topic.

1) Base on manufacturer (branding just like grocery)

Example, Alfa Laval P605, Mitsubishi Selfjector SJ30G(genius series) / SJ30F(future series), GEA Westfalia, Samgong, ALCAP and etc.

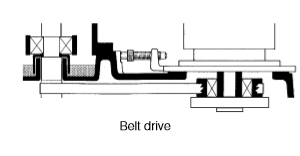

2) Base on it's specification (when we have to concern)

Or

Mitsubishi Selfjector SJ30EH

1800 rev

4400 L/Hr

11 kW

Motor(50/60 Hz) - pulley - friction coupling - belt - spindle shaft

Horizontal shaft

Supported with two end bearings, in between them there is spiral gear.

There is attached gear pump connected with safety joint. To prevent oil leakage, it is provided with the oil seal. The gear driven have compact design when it have pump attached together thus it requires no separate pump unit.

Vertical Shaft

Radially supported by upper springs incorporated at six points.

Vertically supported by lower spring.

On the shaft there is pinion gear profile.

5) When size is m

Mitsubishi SJ model are popular with pilot valve method meanwhile Alfa Laval/GEA Westfalia brand are popular with annular piston.

It also important for us to know that bowl operating mechanism function is to desludge/clean the bowl partially or fully (will be explained further).

For easy understanding, I prefer us to click the video links below that I select from youtube to differentiate those purifiers available on the market regarding their operation focus on bowl desludging methods. Thanks to those who put tremendous efforts in making those videos.

Mitsubishi SJ Model(Pilot valve)

https://www.youtube.com/watch?v=wrqgGNJWbDI

https://www.youtube.com/watch?v=_KtsBe34GHk

Alfa Laval with mechanical spring type

https://www.youtube.com/watch?v=IiEnlgaVIoQ

GEA Westfalia

https://www.youtube.com/watch?v=MtN9jvqgSJ4

source: https://www.youtube.com/watch?v=_7R4tYfdwng

The end....

As for the conclusion, I have stated about 7 ways to understand type of purifiers from very basic logic of grocery to more marine engineering. From very practical to theory and I not intended to focus on the theoretical part in detail. Hopefully it helps to refresh us, relate us with the thing we learned in class or give some exposure and few ideas to those who want to know what marine engineering is, and make us feel passion with our job. Any comments are appreciated in advance. Thank you.

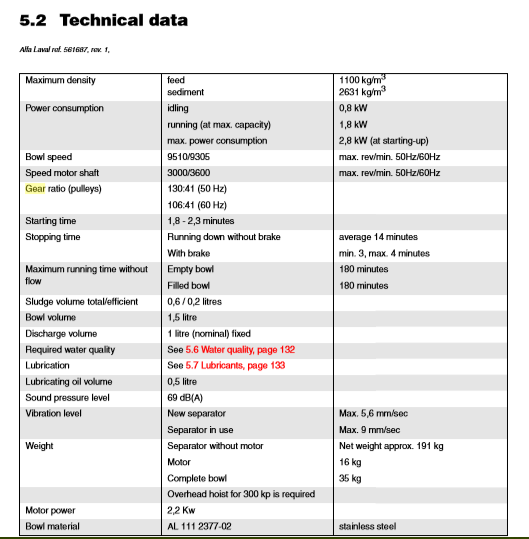

3) Base on driver's mechanism

There are at least two very mechanical mechanisms which are by belting and gearing. This explains on how the electric motor turns the purifier from static to rated rotation speed.

Why not we directly connect the motor and purifier?

Let me try to answer:

So it can slip.... which is necessary in starting when we can reduce starting torque and avoid over current on motor, and also in the event of overload(purifier internally damaged/electric motor failure) occurs in running time.

Second as we can use the gear ratio or belt ratio to have the faster rotation of bowl than the motor which is essential to produce better centrifugal force and better purification.

Second as we can use the gear ratio or belt ratio to have the faster rotation of bowl than the motor which is essential to produce better centrifugal force and better purification.

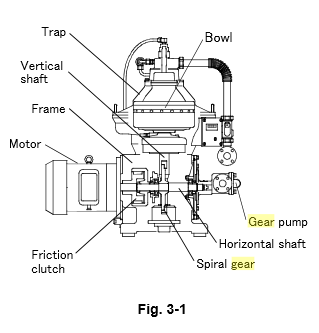

Pictures explain worth: Alfa Laval P605 VS Mitsubishi Selfjector SJ30G

|

| Mitsubishi Selfjector SJ30G (Gearing) |

If we zoom in more (at the end you can make own conclusion which one is better transmisson in term of compact design, safety, easy maintenance and etc) :

1) Alfa Laval P605 -

Motor(50/60 Hz) - pulley - friction coupling - belt - spindle shaft

2) Mitsubishi SJ30G -

Motor - friction clutch - horizontal shaft - spiral gear - pinion gear - vertical shaft

Friction clutch

Friction clutch function is to give soft/gentle starting to reduce motor load in the beginning as by it, the motor will not take 100% of bowl weight instantly. Friction clutch then will start to grip the pulley as it subjected to have centrifugal force radially in time motor accelerates. This is known as the critical speed which is a phase where friction clutch still slipping (for SJ 30, the critical time less than 5 min) before fully grips and turns the bowl to rated speed.

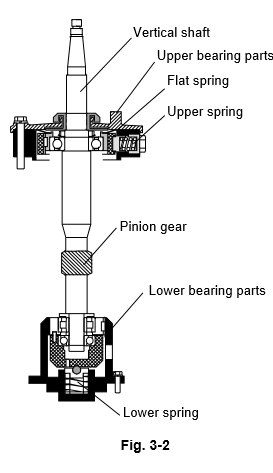

Motor - friction clutch - horizontal shaft - spiral gear - pinion gear - vertical shaft

Friction clutch

Friction clutch function is to give soft/gentle starting to reduce motor load in the beginning as by it, the motor will not take 100% of bowl weight instantly. Friction clutch then will start to grip the pulley as it subjected to have centrifugal force radially in time motor accelerates. This is known as the critical speed which is a phase where friction clutch still slipping (for SJ 30, the critical time less than 5 min) before fully grips and turns the bowl to rated speed.

Horizontal shaft

Supported with two end bearings, in between them there is spiral gear.

There is attached gear pump connected with safety joint. To prevent oil leakage, it is provided with the oil seal. The gear driven have compact design when it have pump attached together thus it requires no separate pump unit.

Vertical Shaft

Radially supported by upper springs incorporated at six points.

Vertically supported by lower spring.

On the shaft there is pinion gear profile.

4) Lubrication method

In order to explain this, I still consistent in comparing Mitsubishi SJ model with Alfa Laval P605. This is because we want to compare between the belt and gear driven purifier lubrication mechanism.

1) Alfa laval P605

For belt type driven purifier, it may have compact design in term of the spindle as instead of only serve as transmission, but also:

- fitted with pump sleeve(b4) to pump closing bowl water

- have hollow spindle for closing water passage

- and who knows also for lubrication of ball bearing. The spindle is equipped with oil pump(b3) which creates oil mist in the sump tank. Then the oil mist will be travel to upper bearing as being suck by fan(b1). The ring shaped rubber buffer(b2) supports upper bearing housing. It is hold by buffer holder which forms channel to recirculated the oil

2) Mitsubishi SJ

The mitsubishi sj model use splash type lubrication by spiral gear.

5) When size is m

atter from Mitsubishi SJ10-70

When we compare with Alfa Laval P605, it also have no heavy liquid impeller.

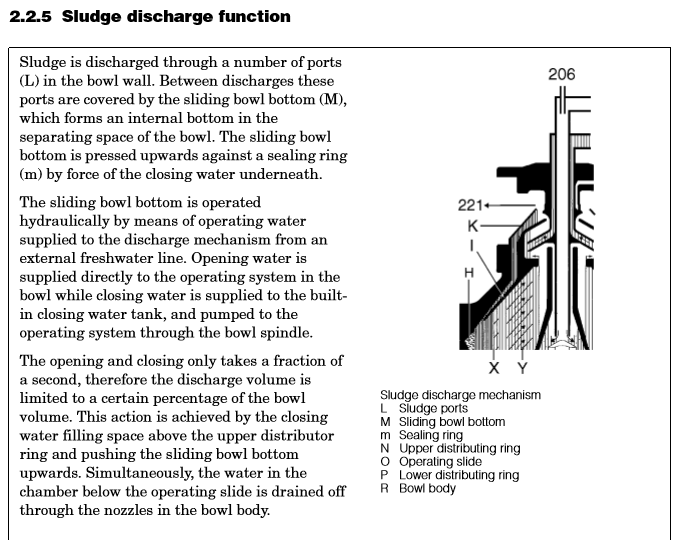

6) Bowl operating mechanism

Generally, bowl is operating by hydraulic (water). Only the mechanism varies by designers. Some even involving mechanical spring for bowl closing but hydraulically for bowl opening.

Mitsubishi SJ model are popular with pilot valve method meanwhile Alfa Laval/GEA Westfalia brand are popular with annular piston.

It also important for us to know that bowl operating mechanism function is to desludge/clean the bowl partially or fully (will be explained further).

For easy understanding, I prefer us to click the video links below that I select from youtube to differentiate those purifiers available on the market regarding their operation focus on bowl desludging methods. Thanks to those who put tremendous efforts in making those videos.

Mitsubishi SJ Model(Pilot valve)

https://www.youtube.com/watch?v=wrqgGNJWbDI

Alfa Laval P605

https://www.youtube.com/watch?v=_KtsBe34GHk

Alfa Laval with mechanical spring type

https://www.youtube.com/watch?v=IiEnlgaVIoQ

GEA Westfalia

https://www.youtube.com/watch?v=MtN9jvqgSJ4

For Mitsubishi SJ and Alpha Laval P605, I can present the manual content for us to get into more detail and together conclude the different in between half and partial desludging specifically to each purifier.

MITSUBISHI (TOTAL DESLUDGE)

MITSUBISHI PARTIAL DESLUDGE

ALPHA LAVAL DESLUDGING

7) ALCAP system

- ALCAP is a system designed for purifying liquid with specfic density more than 0.991.

- It eliminates the gravity disc and applies flow control disc as the density of water and purified oil is not much different.

- At the clean oil outlet, there is sensor for sensing any water carry over and stimulate control unit to drain the sealing water out via flow control disc and drain valve fitted at sealing water outlet line.

- The sealing water also can be drain by normal desludging.

- Control unit is programmed to track the frequent of drain valve activated and time elapse after the last desludge cycle.

source: https://www.youtube.com/watch?v=_7R4tYfdwng

The end....

As for the conclusion, I have stated about 7 ways to understand type of purifiers from very basic logic of grocery to more marine engineering. From very practical to theory and I not intended to focus on the theoretical part in detail. Hopefully it helps to refresh us, relate us with the thing we learned in class or give some exposure and few ideas to those who want to know what marine engineering is, and make us feel passion with our job. Any comments are appreciated in advance. Thank you.

Could you help me to explain how closing water to be sucked through its rotating shaft driven by motor? Which principle is it based on?

ReplyDeletethe bottom part of shaft, there is water pump with vane plate, by enough rotation speed by designer, it can produce suction if you need the picture of water pump pls reply how to send you the picture

Delete